Thermal impulse welding

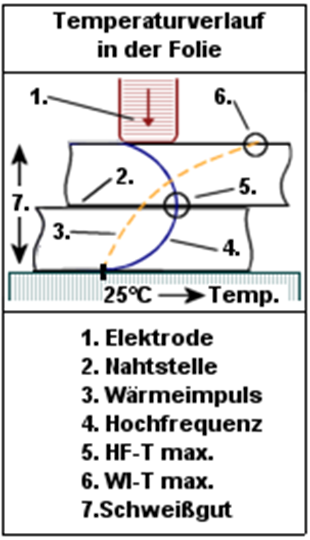

In the case of thermal impulse welding, the welding heat is created in a thin metallic heater band by means of electrical impulses (resistance heating). The heater band is made from a special alloy and can come in the form either of a straight heater band with a welding width of 3 to 45 mm, or as a contoured heater band as required. The welding temperature for this process can be precision regulated. Owing to the low mass of the heater band, it can be heated (to 20 to 200°C in approx. 0.5 seconds) and cooled quickly. The option of further cooling under pressure ensures that the quality of the seam is very high.

This process is particularly well suited for thermoplastic plastic sheets and fleeces (up to 2 x 0.8 mm thick) and for activating hot-melt glues.

Characteristics:

- Excellent seam appearance thanks to cooling under pressure

- Wide range of application options

- Easy to use

- Low investment costs

- Low energy requirement