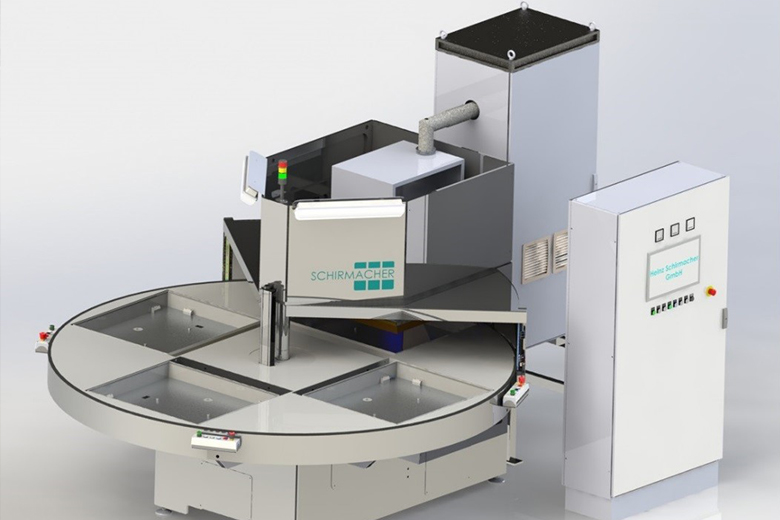

Turntable welding machines

Turntable machines are used where positioning the product being welded requires a lot of time.

The positioning time can be distributed over several workstations so that it can be aligned with the machine’s cycle rate. Turntable machines can be delivered with 4, 6 or 8 planes and individual workstations, or all the workstations can be automated.

Areas of application:

- Sleeves

- Files

- Folders

- Pouches

- Infusion bags

- Blister packs

In order to make the best possible use of welding machinery, the positioning time should be aligned with the machine’s shortest cycle rate. This is chiefly determined by material-related welding and cooling times. This is the best way to exploit the investment in the machinery.

Compared with sliding table machinery, where a maximum of 2 operators can work together, 3 or more people can work on a turntable machine.

Our service team can assist you quickly and competently.

All our customers in the automotive industry have learned to appreciate our fast response times.