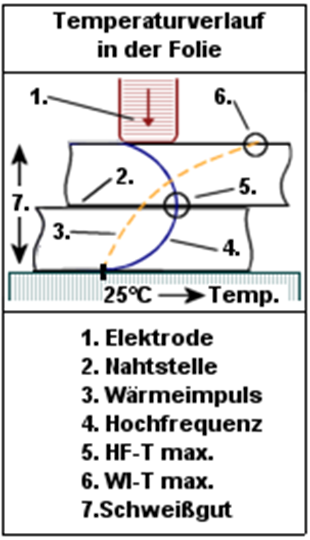

Heat contact welding

In the case of this process, permanently heated welding tools are used to heat the plastic sheet. Thanks to the constant welding temperature, the production cycle time is reduced. A plastic support sheet prevents warping of the seam.

In the case of hot plate welding, a similar type of process, the joint surfaces to be connected are heated by exerting pressure on a permanently heated welding mirror and they are then pressed against one another.

Characteristics:

- Short cycle times

- Can be used with all thermoplastic plastics

Hot plate welding:

- Can also be used for thick-walled components