Service & Tools

Service - personal, reliable, worldwide

At Schirmacher, personal availability is particularly important – because behind every machine are people whose production must run smoothly. Even more important to us is providing fast and sustainable solutions to your challenges.

Our service means fast, responsive support in critical situations, worldwide and carried out by experienced experts. For decades, customers around the world have trusted us, because we don’t just repair – we develop solutions together with you.

Our promise: Keep your machines ready for operation at all times – today and in the future.

Our service areas

We service machines of any brand!

When a breakdown occurs, every minute counts. Our service technicians carry out repairs quickly and reliably – either on-site or in our workshop. Thanks to our extensive spare parts inventory, you receive original components in the shortest possible time, ensuring the operational readiness of your systems.

Please contact us directly:

- info@schirmacher-hf.de

- +49 4154 / 86 16-0

-

Heinz Schirmacher GmbH

Otto-Hahn-Str. 7

D-22946 Trittau

Downtimes in production are avoidable.

Regular inspections and maintenance increase the availability and service life of your systems. To provide you with the best possible support, we offer extended digital services alongside classic maintenance, bundled in various service packages.

Your benefits

- Reduced risk of unexpected system failures

- Lower costs through planned and cost-optimised operations

- Identification of optimisation measures to increase productivity and process reliability

- Employee training following maintenance work

Select your service package or contact us.

- CORE

- Performance

- Performance+

A Successful Start from Day One

Your benefits

- Professional commissioning for the reliable integration of your SCHIRMACHER system into your production processes

- Intensive employee training improves understanding of HF technology and reduces application error

- Production support provides confidence in operating the machine and in introducing new products or materials

- SCHIRMACHER production support helps you to optimise your system productivity

Relocation

- Integration of optimisation measures in the

Reconstruction of the system enables the implementation of new functionalities - Inspection and functional testing of the machine

take place before and during the relocation. This enables us to ensure that

the system is set up in the desired condition - Transport, insurance & logistics are organised

We will take over your request. You can devote yourself to other topics during this time.

Modernisation:

- Improve cycle time & speed

We get the maximum out of your system - without compromising on quality or safety. - Upgrading the control system

Replacement with our powerful, user-friendly control unit - one of the best on the market. - Adaptation to current safety regulations (CE)

Retrofitting in accordance with applicable standards for machine and plant safety. - Conversion to new products or applications

We adapt your system flexibly to changing production requirements. - Modernisation of all machine makes

Regardless of the manufacturer - our experts have the know-how.

Machine purchase:

- Fast and straightforward processing- We take care of evaluation, collection and transport

- Fair market prices - Our experts evaluate your machine transparently and at a fair market value.

- Direct payment - You receive the purchase price quickly and without delays.

- Machinery Directive - We ensure that your system can be safely reintroduced to the market – giving you no risk, unlike a sale to another company.

- Would you like to sell a machine? Please use our contact form directly

Tools/ devices

Efficient and customised tools are a decisive factor for the success of your production. We offer you the complete development and manufacture of tools for high frequency, heat impulse and heat contact welding.

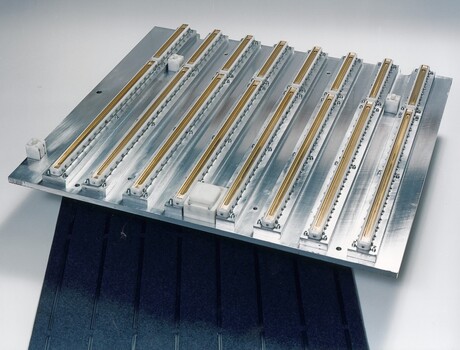

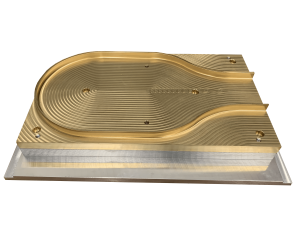

High-frequency welding tools

Schirmacher high-frequency tools combine precision manufacturing with deep expertise in optimal high-frequency distribution. Whether flat, parallel surfaces or complex special contours - we develop tools that are perfectly tailored to your specific requirements. Thanks to intelligent insertion aids and positioning systems, we make even the most demanding projects possible. Our motto: Every contour - as individual as your requirements!

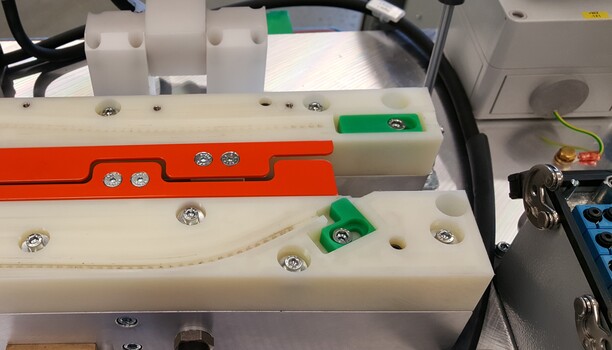

Heat impulse welding tools

Our heat impulse tools impress with the precise implementation of your desired contour in a functional and feasible design. We guarantee efficient heat transfer and rely on thermally optimised solutions for consistent results. Both upper and lower tools are manufactured with perfect precision, using durable, high-quality materials. Thanks to the sophisticated design, the heating wire can be easily replaced when needed, minimising downtime. Functionality and efficiency - perfectly combined!

Heat contact welding tools

Our heat contact welding tools offer even and effective heat transfer for first-class welding results. They are precisely adapted to the material properties to prevent deformation and overheating. Durable, temperature-resistant materials and optimised surfaces protect both the tool and the material. With their energy-optimised design, our tools support a sustainable and performance-oriented production - ideal for a wide range of applications.

Other applications

We also offer toolmaking for a wide range of applications. We approach every challenge with the utmost precision and customer-orientation. If you are unsure whether your project can be realised, we are always available to work with you to find a solution. Do not hesitate to contact us - we will be happy to turn your ideas into reality.

What can we do for you?

We look forward to hearing from you.