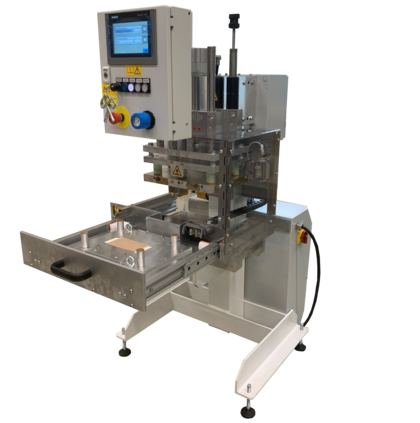

PTP series

The PTP series has been specially developed for demanding applications in heat impulse, heat contact, and optionally high-frequency welding. With its in-house design, modular construction, and well-engineered layout, the series provides the ideal solution for both industrial continuous operation and laboratory applications.

Whether as a stand-alone machine or a bench-top unit, the PTP series offers customised technology for reliable welding results, perfectly adapted to your specific requirements.

Can also be used as an ideal replacement for foot lever welding machines.

AREAS OF APPLICATION

Explore our portfolio and

start your brand transformation.

Automotive Interior

" Logo embossing (airbag, brands)

" Smaller applications

Packaging

" Transparent packaging

" Consumer goods

" Sterile packaging

" Coin sleeves

" Tubular bag

Outdoor & Defence

" Bicycle trousers (gel pads)

" Cycling gloves

" Safety gloves (military)

" Headphone ear pads (Hifi, Aviation)

More

" Material tests

" Laboratory tests

" Smaller applications

Own construction

Developed and manufactured to the highest standards of quality and durability.

Pneumatic pressure system

Precise and reliable for consistent results.

Customised control

Developed and programmed according to your specific requirements.

Integrated energy source

Compact and installed directly in the machine.

Ergonomic operation

Optionally with two-hand control for additional safety.

Welding with safety

Fully shielded working area in accordance with CE/EMC regulations for optimum protection against HF radiation.

Choice of heat, impulse or high-frequency welding unit

PTP Series: Versions Overview

Compact design:

The PTP 50 is designed as a space-saving bench-top welding system - ideal for use in laboratories, quality assurance or for small batches. The generator is integrated under the table.

Versatile in use: Whether high-frequency, heat pulse or heat contact welding - the PTP 50 can be used flexibly and covers all common processes.

Ergonomic single workstation:

Thanks to the height adjustment and table frame, the machine is suitable for both standing and seated operation - perfect as an ergonomic individual workstation.

Simple operation & quick conversion:

The PTP 50 is intuitive to operate. Tools can be changed quickly - ideal for changing requirements.

Technical data

- Construction method: 1 cylinder pneumatic press

- Control: Pneumatic control of the cylinder + electrical power control

- Operation: Manual

- Table dimensions (LxWxH): 1500mmx700mmx 850mm

Optional extensions:

- Height adjustable: The machine is height-adjustable and can therefore be flexibly adapted to the operator or a production line.

- Cleanroom suitability: Fulfils special requirements for dust and contamination prevention. The machine is designed to be easy to clean, making it ideal for cleanroom applications.

Flexible platform:

The PTP 470 forms the basis for various versions: with sliding table, fixed table or as a built-in version in automation lines.

Suitable for industrial use & stable:

Thanks to the modular steel frame, the PTP 470 offers maximum stability and can be customised to individual production processes.

Integrated welding unit:

The generator is permanently installed in the machine frame. The system forms a closed unit for high production reliability.

Individually configurable:

Available for heat impulse or heat contact welding - with selectable table size, suitable clamping devices and automated on request.

Technical data

- Construction method: 4-column press

- Control: Siemens control, pneumatic

- Operation: Manual or fully automated in your product line

Optional extensions:

- Height adjustable: The machine is height-adjustable and can therefore be flexibly adapted to the operator or a production line.

- Sliding table: Equipped with a sliding table for easy insertion of material and higher process speed

- Single seat: Ergonomic design incl. table frame and height adjustment for use as a standing or sitting workstation

- Cleanroom suitability: Fulfils special requirements for dust and contamination prevention. The machine is designed to be easy to clean, making it ideal for cleanroom applications.

Schirmacher Tool

Protection (STP)

Protects your tools in the event of flashovers, reduces downtimes and maximises the service life of the tools.

High- Dynamic

HF Control

Ensures consistent, precise welding results even under changing production conditions.

DDM (Dynamic Data Monitoring)

Monitor all machine data at all times and gain valuable insights into performance, efficiency and operating statuses in order to continuously optimise production processes.

Remote Service

Remain flexible and efficient - our remote service function allows you to quickly diagnose and monitor the machine from anywhere.

Touchpad Control

Optional: Touchpad with Siemens SIMATIC S7 controller: This advanced controller offers user-friendly operation and is ideal for automation solutions thanks to its open interface.

SSG (Schirmacher Shield

Guarding

Prevents malfunctions on other machines and offers maximum safety for production and employees.

Get in touch with us today.

We look forward to hearing from you.