TSM

TSM

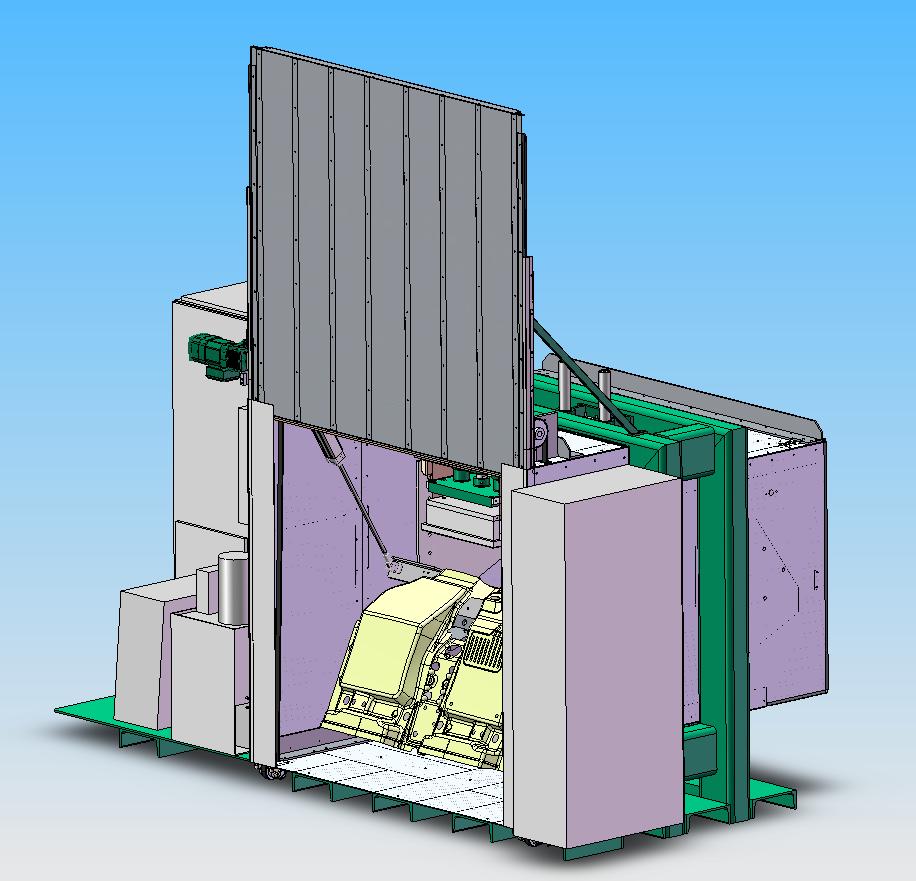

The TSM series stands out for its modular and robust design. Years of experience and continuous optimisation of the systems ensure an optimal welding process, even under the most demanding conditions. By utilising and combining state-of-the-art technologies, these machines offer ideal performance and efficiency throughout the entire product life cycle. Our machines are already used today in the production of automotive carpets for renowned manufacturers such as BMW, Ford, Mercedes, Opel, Porsche, VW, Škoda, SEAT, Renault, Peugeot, Hyundai, and Toyota. Trust in the technology of the market leader.

AREAS OF APPLICATION

Automotive industry

Market leader in your field

Our high-frequency welding machines for heel pad films are based on over 50 years of experience. They offer precise weld seams and maximum reliability - ideal for durable and efficient heel pad solutions.

Hydraulic bridge press with central round column guide

The entire TSM series is based on the proven Schirmacher principle of a central round column guide, combined with high hydraulic pressure, to ensure exceptional stability and precision during the welding process. An essential factor when processing difficult-to-weld carpet materials.

Customised assembly of the individual welding systems

Our welding systems can be individually configured and combined with each other as required, regardless of material and application. Whether footrest, pedal passage, heel support or right/left-hand drive - we ensure that you always receive the optimum solution for your specific requirements. In addition, different systems can be used together in a single operation.

Maximum workplace safety

Comprehensive shielding during the welding process, coupled with safety technology from renowned manufacturers - this combination guarantees maximum safety and protects your employees.

Customised tool changing systems

Our changing systems simplify replacement and at the same time reduce production costs thanks to their modular design. They enable intuitive and user-friendly replacement, which is easy to handle even for inexperienced operators.

There is also the option of a semi-automated tool change.

Modular construction concept

This technology allows the carpet welding systems to be customised to your production requirements. With ready-made concepts, the machines can be extended or retrofitted as required to ensure that they always meet the latest customer requirements.

TSM Series: Versions Overview

Technical data:

- Table size 2200x 1700mm (other table sizes and designs available on request)

- Compressive force 50 kN, hydraulic (higher compressive force available on request)

- Generator output: 25 or 45 kW (depending on the materials to be welded)

Technical data:

- Table size 2200x 1700mm (other table sizes and designs available on request)

- Compressive force 50 kN, hydraulic (higher compressive force available on request)

- Generator output: 25 or 45 kW (depending on the materials to be welded)

Technical data:

- Table size 2200x 1700mm (other table sizes and designs available on request)

- Compressive force 50 kN, hydraulic (higher compressive force available on request)

- Generator output: 25 or 45 kW (depending on the materials to be welded)

Technical data:

- Table size 2200x 1700mm (other table sizes and designs available on request)

- Compressive force 50 kN, hydraulic (higher compressive force available on request)

- Generator output: 25 or 45 kW (depending on the materials to be welded)

Technical data:

- Table size 1700x 1200mm

- Compressive force 50 kN, hydraulic (higher compressive force available on request)

- Generator output: 10, 25 or 45 kW (depending on the materials to be welded)

Specifically optimised for the dedicated welding of heel pad films used as footrests. Thanks to its compact design, it is ideal for tight production spaces and enables efficient processing without compromising quality.

Technical data:

- Table size 1500x 1350mm

- Compressive force 10 kN, hydraulic

- Generator output: 10kW

Schirmacher Tool

Protection (STP)

Protects your tools in the event of flashovers, reduces downtimes and maximises the service life of the tools.

High- Dynamic

HF Control

Ensures consistent, precise welding results even under changing production conditions.

DDM (Dynamic Data Monitoring)

Monitor all machine data at all times and gain valuable insights into performance, efficiency and operating statuses in order to continuously optimise production processes.

Remote Service

Remain flexible and efficient - our remote service function allows you to quickly diagnose and monitor the machine from anywhere.

Touchpad Control

Touchpad with Siemens SIMATIC S7 controller: This advanced controller offers user-friendly operation and is ideal for automation solutions thanks to its open interface.

SSG (Schirmacher Shield

Guarding

Prevents malfunctions on other machines and offers maximum safety for production and employees.

Get in touch with us today.

We look forward to hearing from you.