Forsstrom tarpaulin welding machines

We, Heinz Schirmacher GmbH, have been the exclusive sales and service partner of the Swedish company Forsstrom in Germany for over 15 years. As the market leader for high-frequency welding systems, we are rounding off our portfolio with this co-operation. Based on our many years of experience, we can therefore offer you first-class advice on the entire Forsstrom product range.

These machines are the first choice when it comes to reliably welding tarpaulin or tent fabrics of any size and type.

Contact us directly so that we can advise you specifically for your application

AREAS OF APPLICATION

Explore our portfolio and

start your brand transformation.

Tarpaulin fabrics/ tents

» Tents

» Stretch ceilings

» Pavilions

» Tarpaulin eyelets

Inflatable objects

» Oil booms

» Water barriers

» Buoyancy chamber

» Liquid tanks

Various

» Sun protection systems

» Swimming pool linings

» Swimming pool covers

» Production screens

» Stretch ceilings

» Biogas plant covers

» Cinema screens

» Awnings

One of the market leaders in HF welding technology for tarpaulin fabrics

Forsstrom stands for top quality worldwide - like a premium vehicle in its class: durable, precise, reliable. Choosing Forsstrom means investing in the best solution on the market.

Highest availability & German service

Minimised downtimes and maximum production reliability - combined with direct service and support from Germany.

Flexibility thanks to customisable table lengths & configuration according to customer requirements

Thanks to its consistent design as a lifting table press, this series achieves a centred feed of the HF and therefore a more even distribution of energy - a decisive advantage over other manufacturers

More productivity through automation & presets

Intelligent automation and memorisable presettings reduce set-up times, avoid errors and ensure consistently high quality.

Forsstrom Series: Versions Overview

Stationary machines

The entry-level model from Forsstrom - small, compact and powerful!

The machine is stationary, without traction drive, but can be supplied on castors so that it can be moved around the workshop.

Apart from that, the Forsstrom TX offers all the features of the large welding machines and thus offers a top price-performance ratio.

Technical data:

- 5- 12 kW HF power

- 200-500cm² Welding surface

- 750mm Free space behind the electrode

- 75mm Maximum lifting height

Technical data:

- 10- 20 kW HF power

- 400-800cm² Welding surface

- 880mm Free space behind the electrode

- 75mm Maximum lifting height

The Forsstrom DR is particularly suitable for welding large-area products. For this purpose, the machine frame has been modified to create additional free space behind the electrode. In addition, the distance between the welding electrode and the earth electrode can be extended to up to 250 mm. This model is rounded off by a large welding table.

Technical data:

- 5- 12 kW HF power

- 200-500cm² Welding surface

- 1500mm Free space behind the electrode

- 160mm Maximum lifting height

The Forsstrom XP is particularly suitable for smaller welding areas. Whether test welds in your laboratory or the embossing of logos. A wide variety of applications are possible with this machine. The Forsstrom XP is also indispensable when it comes to detailed and fine welds with small electrodes. It can be equipped with both a free arm and a small welding table.

Technical data:

- 2- 5 kW HF power

- 80-200cm² Welding surface

- 123mm Maximum lifting height

The MG Flex 300 is a compact HF welding machine with a 180° swivelling head. The 180° rotation is a useful tool in the HF welding process and makes it easier for the operator to weld heavy materials.

The machine can also be moved on wheels so that large and heavy tarpaulins can be welded without the need for time-consuming movement

Technical data:

- 8 kW HF power

- 300cm² Welding surface

- 690mm Free space behind the electrode

- 190mm Maximum lifting height

The MG L500-800 is a compact HF welding machine with a 180° swivelling head. The 180° rotation is a useful tool in the HF welding process and makes it easier for the operator to weld heavy materials.

This machine is the larger alternative to the well-known MG-Flex 300.

The MG series is also mobile on wheels so that large and heavy tarpaulins can be welded without having to move them.

Technical data:

- 12-20 kW HF power

- 500-800cm² Welding surface

- 888mm Free space behind the electrode

- 95mm Maximum lifting height

Mobile machines

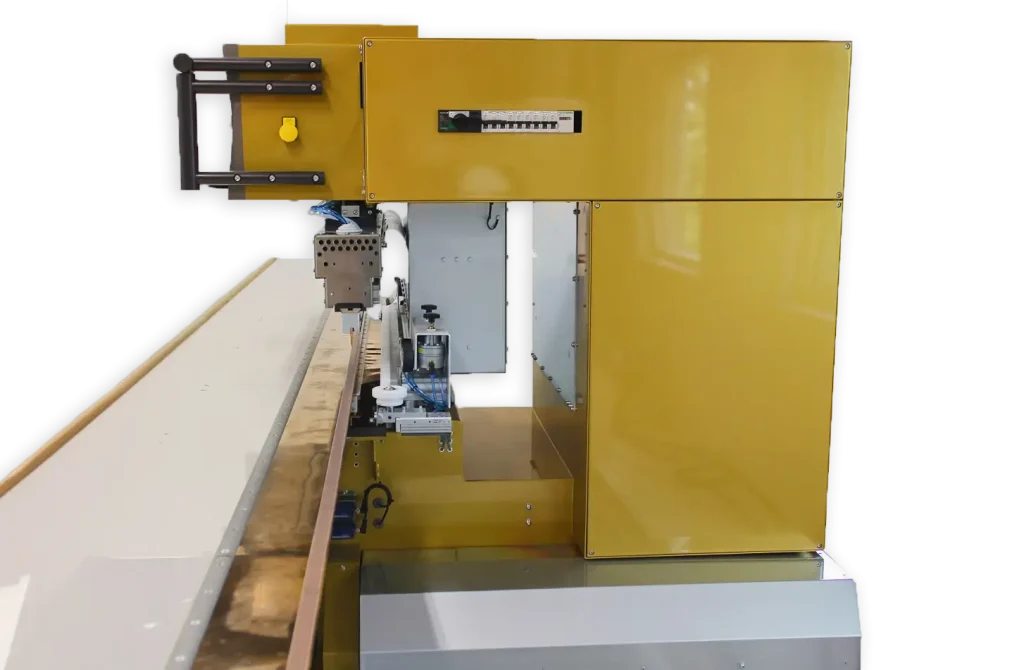

The TDW is a mobile longitudinal welding machine with which extensive work areas can be efficiently covered.

All longitudinal welding machines are equipped with an adjustable table length.

The TDW machine is equipped with plenty of space behind the electrode (785 mm), which gives the operator the necessary room for easy manoeuvring and material handling.

Technical data:

- 5- 25 kW HF power

- 200-1000cm² Welding surface

- 785mm Free space behind the electrode

- 70mm Maximum lifting height

The TDW-Mega was developed at the request of our customers. The model is based on the TDW chassis. Thanks to a larger machine frame and a different arrangement of the recirculation system, you can weld even larger areas. At the same time, the maximum generator output is increased accordingly. The welding width of 400 mm expands the possibilities for welding large products and provides scope for productions that require different types of additional tools, e.g. circumferential seams.

We supply the TDW-Mega (16-25 kW) with a table of any length with a tray for material storage. This model can also be equipped with an extended stroke length, which increases production flexibility by enabling the handling of thicker materials.

Technical data:

- 16- 25 kW HF power

- 650-1000cm² Welding surface

- 825mm Free space behind the electrode

- 70mm Maximum lifting height

Technical data:

- 16- 30 kW HF power

- 650-1200cm² Welding surface

- 820mm Free space behind the electrode

- 80mm Maximum lifting height

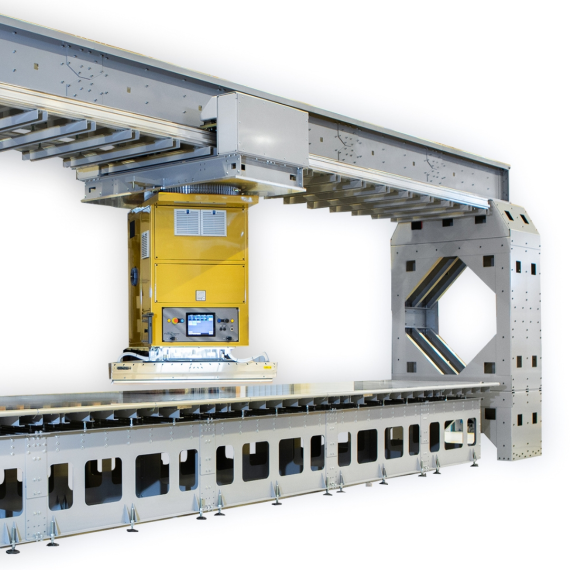

The Forsstrom TDO offers a suspended welding head on a robust steel frame.

The frame can be customised. The suspended design of the model offers unlimited space and is therefore perfect for large-scale productions such as marquees and high-speed doors. Say goodbye to cumbersome material handling and look forward to optimised processes.

Technical data:

- 8- 20 kW HF power

- 300-800cm² Welding surface

- 80mm Maximum lifting height

- No restrictions on the Free space behind the electrode

The TG-90 Mega is Forsstrom's latest addition to the range of mobile gantry welding machines. Designed to minimise handling and increase the productivity of our customers in an efficient and economical way.

This system offers both manual rotation of the welding head by 180° and a lateral movement of 600 mm. This manoeuvrability is ideal for intricate contours and complex weld seams.

Technical data:

- 8- 25 kW HF power

- 320-1000cm² Welding surface

- 80mm Maximum lifting height

- No restrictions on the Free space behind the electrode

- 180° Rotatable welding head (manual)

The TG-Flex was developed to process even particularly large products cost-effectively.

The welding head can be rotated 360° and adjusted by +/- 600 mm in the transverse direction.

The control panel is located both on the system and on the welding head.

This sophisticated control and handling gives you maximum flexibility in production.

Technical data:

- 8-25 kW HF power

- 300- 1000cm² Welding surface

- 80mm Maximum lifting height

- No restrictions on the Free space behind the electrode

- 360° Rotatable welding head (automatic, programmable)

The Forsstrom TDP is a HF welding machine with a stable TD stand that can be moved in the longitudinal direction. One or two work platforms are located on the sides of the machine, on which the machine operator moves along during the welding process. This allows the entire length of the table to be utilised efficiently. The welding table length is customised to the customer's requirements.

Technical data:

- 5-12 kW HF power

- 200-500 cm² Welding surface

- 520mm Free space behind the electrode

- 80mm Maximum lifting height

Special machines

The companies Forsstrom and Carmo developed the CP9 series together. The aim was to optimise the production process for welding tarpaulin eyelets. They succeeded in developing a machine that completes the setting, punching and welding of a plastic eyelet in just one operation (all-in-one process). This allows you to achieve the shortest production time with the CP9. The CP9 can be coupled with an existing Forsstrom machine or operated on its own.

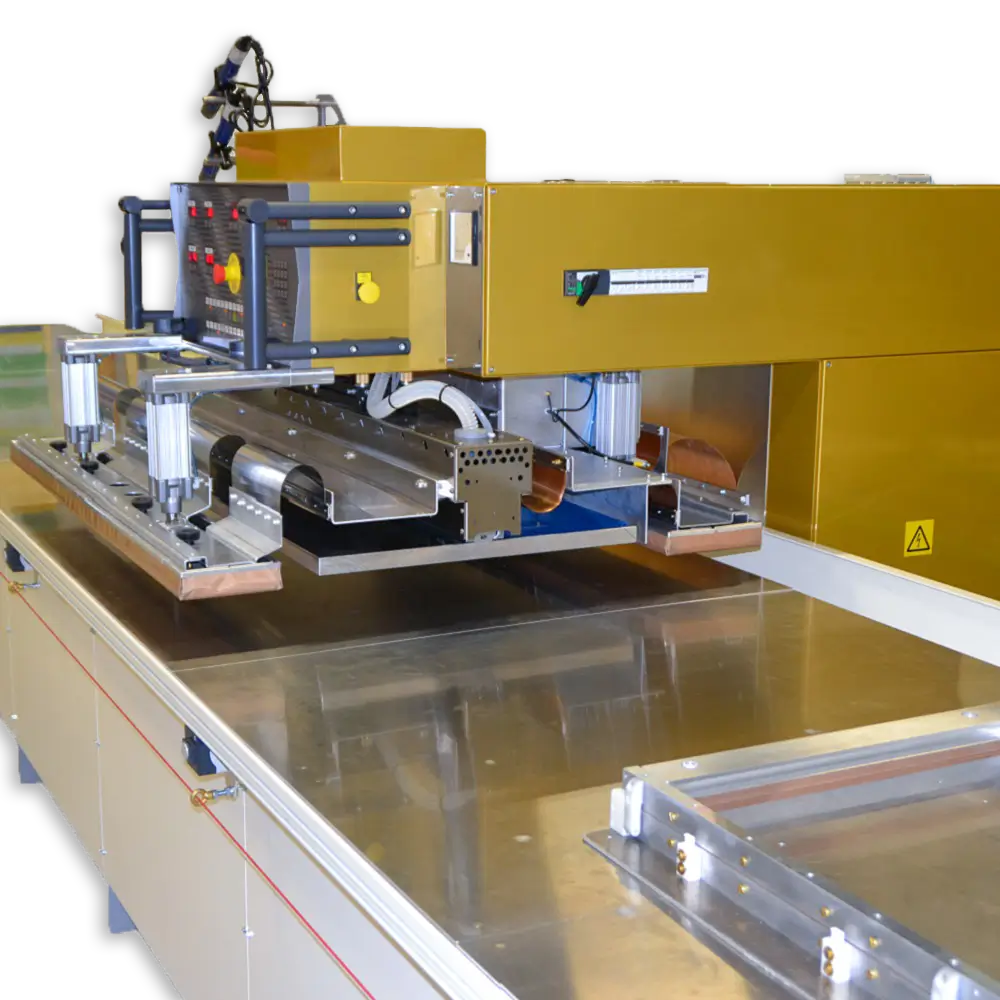

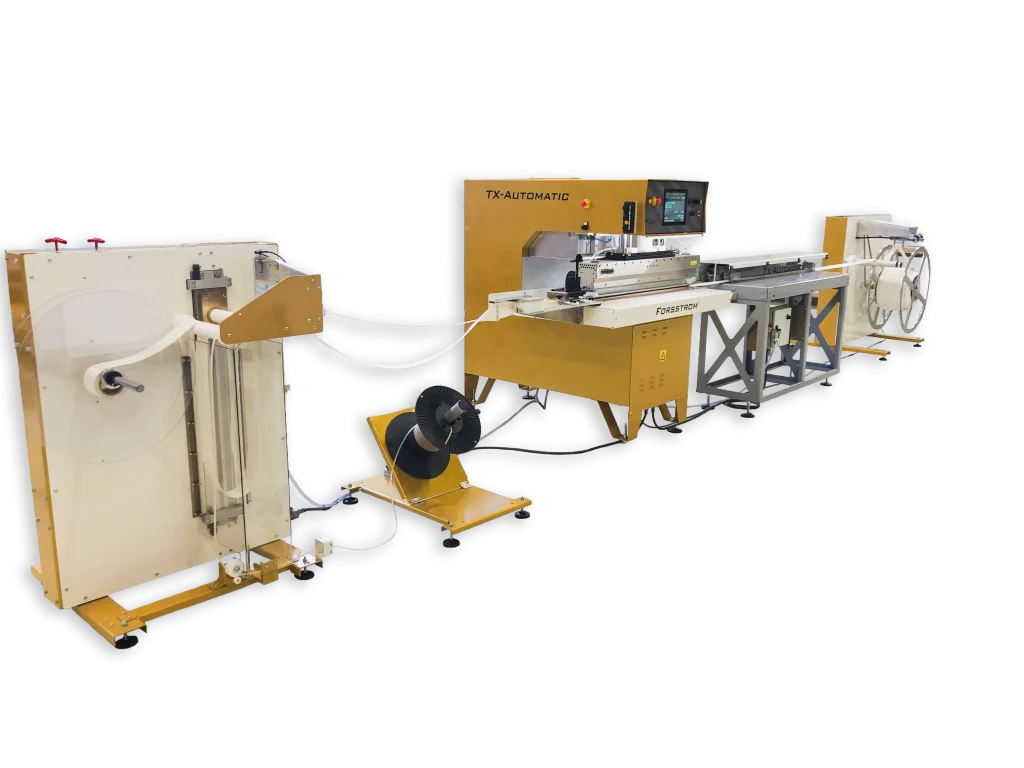

The Forsstrom TX Automatic is a fully automatic high-frequency welding machine for continuous production. In addition to the welding machine, it includes an unwinding and indexing unit and, if required, a rewinding unit. Depending on the end product, the TX Automatic has a production capacity of 200 to 300 metres/hour. With the TX Automatic you can produce piping, tubes etc. in an automatic continuous process.

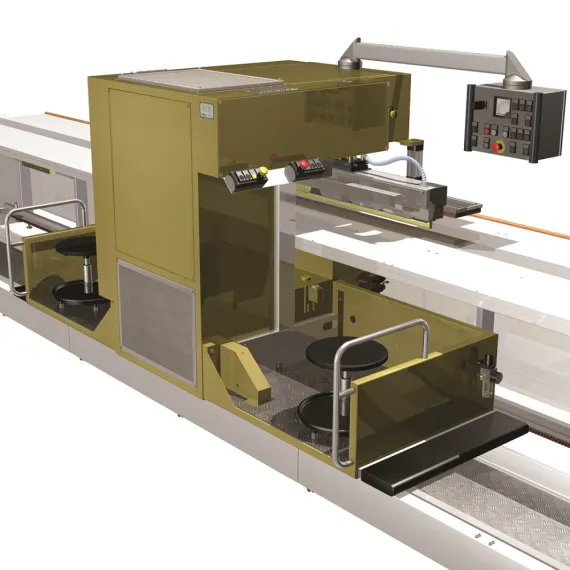

The TD-Ceiling from Forsstrom is a turnkey solution that has been specially developed for the production of high-quality stretch ceilings and canvases. It has functions for cut/iron welding and edge welding (piping), all in one machine.

The TD-Ceiling has two HF power levels (5 kW/10 kW) to enable welding with both thin cutting edge electrodes and wider electrodes. This mobile HF welding machine has all the technology and tools required for high accuracy and straight, continuous weld seams in the production of stretch ceilings.

Technical data:

- 5/ 10 kW HF power

The Forsstrom iM series offers a modern solution for the Impulse welding - a combination of automation and manual control. All movements are automatic, while the settings can be customised. The series is particularly suitable for Roller blinds, sun protection and textile products.

Three variants - to suit your requirements

iP Impulse Welder

Getting started made easy - powerful for growth. Easy to operate, versatile and expandable with optional guides.iM Impulse Welder

The fastest pocket machine on the market. Automatic hem and pocket production, clear workflows and flexible programming.iG Impulse Welder

Fully electric, fully automatic, fully under control. With HMI control, automatic stop and welding functions and fully programmable sequences.

All models work safely with approved protective elements such as Safety light curtains and are designed for different types of fabric.

Technical data:

- 5-12 kW HF power

- 200-500 cm² Welding surface

- 520mm Free space behind the electrode

- 80mm Maximum lifting height

For further information:

We look forward to hearing from you.