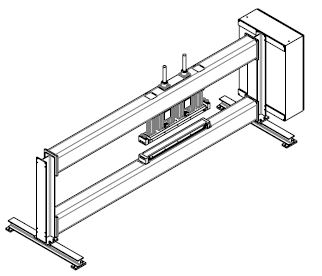

ISM series

ISM

Our ISM Series with heat impulse technology enables the optimal welding of conveyor belts.The double-sided heated welding bars significantly reduce both heating and cooling times, accelerating the production process and lowering energy consumption. The system can be mounted on a frame, making it much easier to work with endless belts. For even more efficient cooling and shorter cycle times, an optional cooling unit is available.

AREAS OF APPLICATION

Explore our portfolio and

start your brand transformation.

conveyor belts

» Joining of conveyor belts

Own construction

Developed and manufactured to the highest standards of quality and durability.

Pneumatic pressure system

Precise and reliable for consistent results.

Customised control

Developed and programmed to fulfil your individual requirements. Simple operation for the employee.

Integrated energy source

Compact and built directly into one unit. Enables the machine to be moved easily to the place of use.

Ergonomic operation

Machine frame adjusted to the ergonomically prescribed working height. Convenient operation via foot pedal.

Extremely short cycle times

We have continuously developed the machine to keep cycle times as short as possible.

Our machine combines the optimum combination of heating tape, cooling and precise machine frame to form a perfect unit.

ISM Series: Versions Overview

Technical data:

- Pulse generator incl. control and user-friendly operation

- Automatic cycle time

- Opening and closing of the unit supported by gas pressure dampers

- Welding time and temperature can be set independently of each other

Technical data:

- Pulse generator incl. control and user-friendly operation

- Automatic cycle time

- Opening and closing of the unit supported by gas pressure dampers

- Welding time and temperature can be set independently of each other

Technical data:

- Pulse generator incl. control and user-friendly operation

- Automatic cycle time

- Opening and closing of the unit supported by gas pressure dampers

- Welding time and temperature can be set independently of each other

Technical data:

- Pulse generator incl. control and user-friendly operation

- Automatic cycle time

- Opening and closing of the unit supported by gas pressure dampers

- Welding time and temperature can be set independently of each other

Schirmacher Tool

Protection (STP)

Protects your tools in the event of flashovers, reduces downtimes and maximises the service life of the tools.

High- Dynamic

HF Control

Ensures consistent, precise welding results even under changing production conditions.

DDM (Dynamic Data Monitoring)

Monitor all machine data at all times and gain valuable insights into performance, efficiency and operating statuses in order to continuously optimise production processes.

Remote Service

Remain flexible and efficient - our remote service function allows you to quickly diagnose and monitor the machine from anywhere.

Touchpad Control

Touchpad with Siemens SIMATIC S7 controller: This advanced controller offers user-friendly operation and is ideal for automation solutions thanks to its open interface.

SSG (Schirmacher Shield

Guarding

Prevents malfunctions on other machines and offers maximum safety for production and employees.

Get in touch with us today.

We look forward to hearing from you.