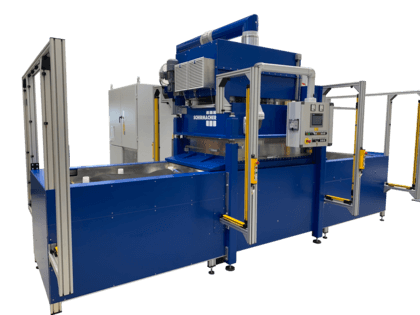

B10000

B10000

The B10000 series sets new standards in industrial production. With its solid construction and the ability to process even larger products, it combines our many years of experience with state-of-the-art technology. The machine delivers extremely high pressing forces and is ideal for demanding applications where maximum performance is required. Thanks to its robust steel construction, the B10000 series ensures reliable welding processes even for large welding areas - a perfect solution for the production of large-format components in areas such as automotive or industrial manufacturing.

AREAS OF APPLICATION

Explore our portfolio and

start your brand transformation.

Automotive Interior

» Trunk covers

» large embossings

» Door panelling

» Further vehicle interior

Particle foaming & insulation

» Particle foam processing EPE

» EPS/eTPU foam

More

» Roller shutters

» Cycling clothing

» MRT covers

» large tanks

» Load securing nets

High process stability

Stable, torsion-resistant plates and guides ensure consistently, high-quality welding results even at high production speeds

Intuitive machine operation

Intuitive touchscreen control reduces familiarisation times for new employees and simplifies recipe selection or welding parameter adjustment

Design as lift table press

Thanks to its consistent design as a lifting table press, this series achieves a centred feed of the HF and therefore a more even distribution of energy - a decisive advantage over other manufacturers

Perfect welding results

Highly dynamic HF control not only ensures consistent welding results, but also prevents ultra-fast flashovers in the welding process

Maximum workplace safety

Fully shielded welding area and accident protection in accordance with CE and BG regulations ensure maximum safety on and around the machine

Different table designs

Versions Available with fully automatic double or multi-level sliding table depending on production requirements

Fully automated production lines with robotic assembly

The welding machine can be extended with a pick-and-place robot for even greater production efficiency

B10.000 Series: Versions Overview

Operation with two operators: Enables simultaneous processing by two employees.

Seamless integration into existing production lines: The system can be easily integrated into existing production processes.

Flexible tool configuration: Two different lower tools can be used in parallel Alternatively, one upper tool can be used simultaneously on both sliding tables.

Optionally also available as a single sliding table: The system is also available in a version with just one sliding table, ideal for smaller production requirements or limited space.

Technical data:

- Effective area 1500 x 1300 mm (other table sizes and designs available on request)

- Compressive force 100, 300 or 500 kN, hydraulic

- Generator output: 25kW, 45kW (depending on the materials to be welded)

Operation with one or two operators: The system can be controlled by one operator. In a longitudinal arrangement, two operators can also be used.

Space-saving, vertical design: With two work tables positioned one above the other, the system makes optimum use of the available space.

Ideal for complex processes: The division of complex insertion work onto two separate tables enables simple separation of the work steps.

Technical data:

- Effective area 1500 x 1300 mm (other table sizes and designs available on request)

- Compressive force 100, 300 or 500 kN, hydraulic

- Generator output: 25kW, 45kW (depending on the materials to be welded)

Schirmacher Tool

Protection (STP)

Protects your tools in the event of flashovers, reduces downtimes and maximises the service life of the tools.

High- Dynamic

HF Control

Ensures consistent, precise welding results even under changing production conditions.

DDM (Dynamic Data Monitoring)

Monitor all machine data at all times and gain valuable insights into performance, efficiency and operating statuses in order to continuously optimise production processes.

Remote Service

Remain flexible and efficient - our remote service function allows you to quickly diagnose and monitor the machine from anywhere.

Touchpad Control

Touchpad with Siemens SIMATIC S7 controller: This advanced controller offers user-friendly operation and is ideal for automation solutions thanks to its open interface.

SSG (Schirmacher Shield

Guarding

Prevents malfunctions on other machines and offers maximum safety for production and employees.

Get in touch with us today.

We look forward to hearing from you.